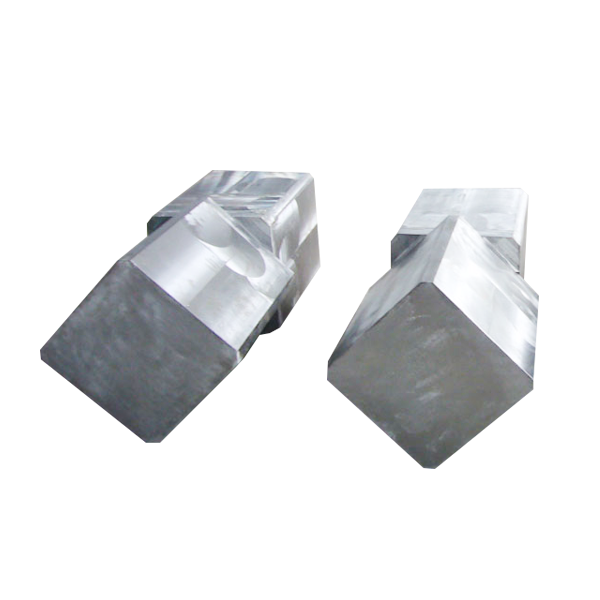

Square Forging

Classification:

Product Introduction

Square forgings are a type of metal component widely used in industrial manufacturing and machinery. They are characterized by their strength and durability, and are commonly applied in various mechanical structures, automotive manufacturing, shipbuilding, and bridge construction. The following will introduce square forgings from the aspects of basic concepts, characteristics, manufacturing processes, and application fields.

I. Basic Concepts

Square forgings are metal parts made through forging processes, typically in square or rectangular shapes. The materials can include carbon steel, alloy steel, stainless steel, etc., and they possess good wear resistance, corrosion resistance, and high strength.

II. Characteristics

1. High Strength: Square forgings undergo forging processes that optimize the internal structure of the metal, resulting in high strength and tensile properties.

2. Good Wear Resistance: The materials of square forgings usually have good wear resistance, allowing them to adapt to harsh working environments.

3. Corrosion Resistance: Square forgings made from corrosion-resistant materials such as stainless steel can be used for long periods in humid and corrosive environments.

4. High Precision: The forging process allows square forgings to achieve high dimensional accuracy and surface quality.

III. Manufacturing Process

The manufacturing process of square forgings includes steps such as raw material preparation, forging, heat treatment, and inspection. First, appropriate metal materials are selected as raw materials; then, the raw materials are plastically deformed using forging equipment to form the desired shape; next, heat treatment is performed to improve the metal properties; finally, quality inspection is conducted to ensure product quality.

IV. Application Fields

Square forgings are widely used in the following fields:

1. Machinery Manufacturing: Used to manufacture various mechanical structural parts, transmission components, etc.

2. Automotive Manufacturing: Used to manufacture parts such as automotive engines, gearboxes, and suspension systems.

3. Shipbuilding: Used to manufacture ship structures, shafts, and other components.

4. Bridge Construction: Used to manufacture supporting structures and piers for bridges.

5. Other Fields: Also applied in industrial fields such as petroleum, chemical, and electric power.

In summary, square forgings are important metal components with a wide range of applications. Their advantages include high strength, good wear resistance, and corrosion resistance. By understanding their basic concepts, characteristics, manufacturing processes, and application fields, one can better understand and utilize square forgings.

Qualification Honor

Product Consulting

If you want to ask questions, we will send experts to contact you within one working day. Please leave your contact information.